RW Westcapper®

The RW Westcapper® is a fully automated, constant motion, rotary crimper. Ideal for large production runs of time sensitive products such as lyophilized vaccines the Genesis RW Westcapper® is capable of sealing parenteral vials at up to 750 vials per minute.

![]()

The Industry Standard in Parenteral Vial Sealing

Genesis Packaging Technologies stands at the forefront of parenteral vial sealing, offering advanced solutions that ensure container closure integrity (CCI) for critical injectable pharmaceuticals. With over 75 years of expertise, Genesis has developed the RW Westcapper®—a high-speed, fully automated rotary crimper designed to meet the rigorous demands of modern pharmaceutical manufacturing.

A stoppered vial is a prevalent parenteral drug container closure system. The system however should not be considered integral until the rubber stopper is crimped firmly in place with sufficient compression against the vial, assuring all potential leakage is cut off at the seal interface. It is well understood that seal quality is critically important to maintaining sterility and stability of the drug product.

Ensuring Container Closure Integrity in Parenteral Packaging

In parenteral drug delivery, the integrity of the container closure system is paramount. A stoppered vial achieves true integrity only when the elastomeric stopper is compressed adequately against the vial’s sealing surface and secured with a crimped aluminum ferrule. This compression ensures a hermetic seal, preventing microbial ingress and maintaining the sterility and stability of the drug product.

The RW Westcapper® addresses this critical aspect by precisely controlling the force applied during the crimping process. By regulating the compression of the elastomeric closure, the system minimizes variability, resulting in consistent and reliable seals across production batches.

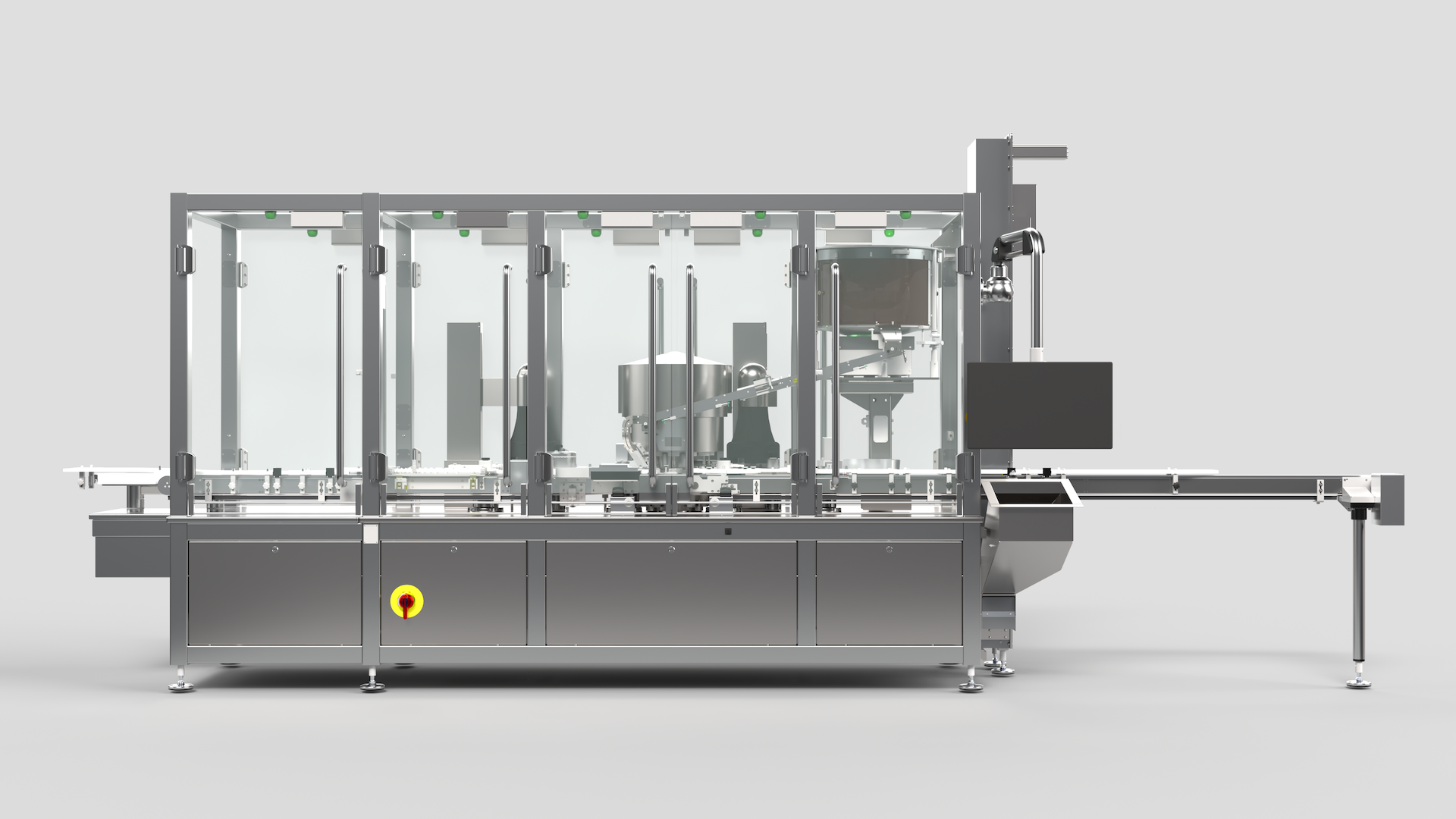

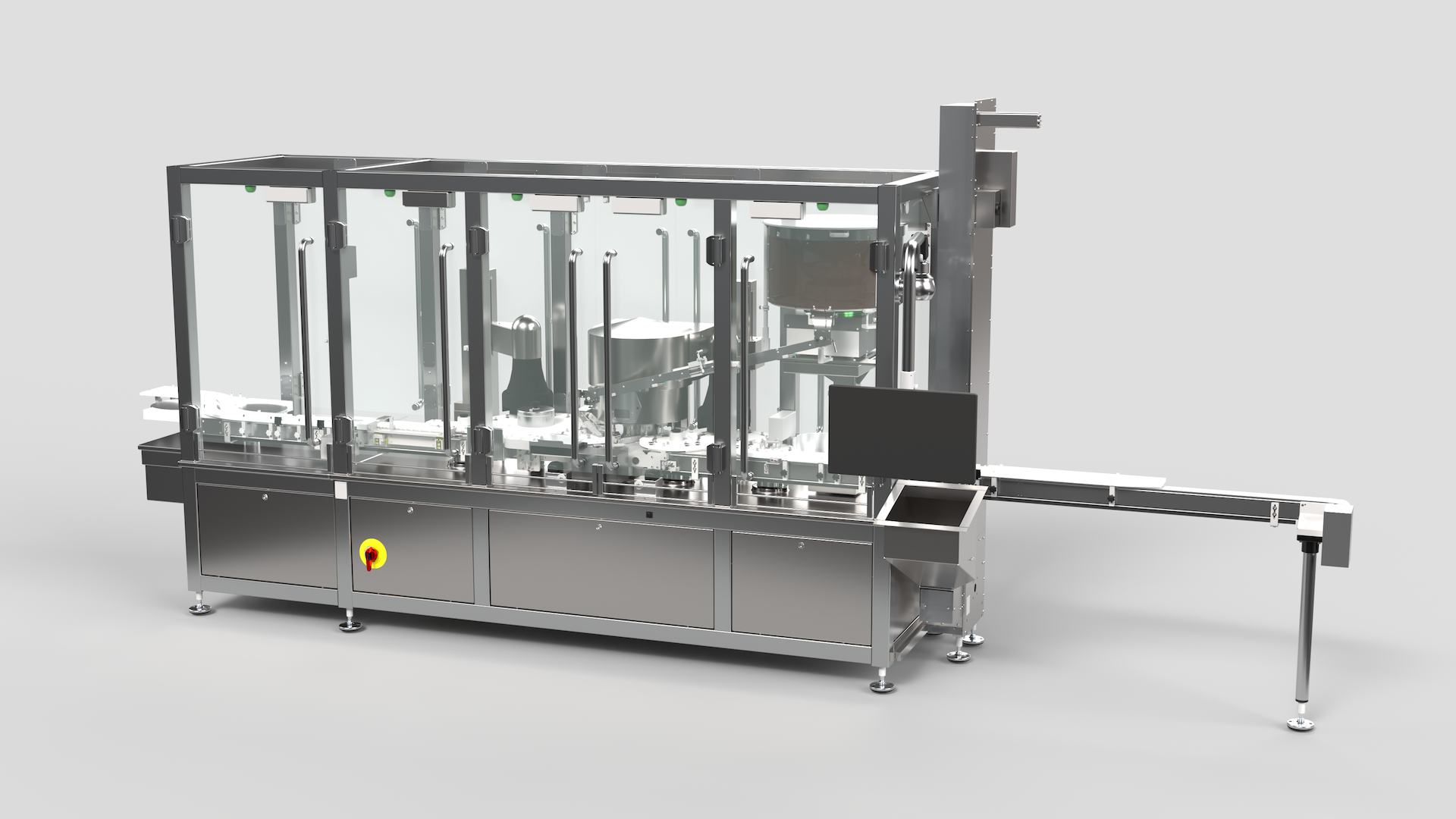

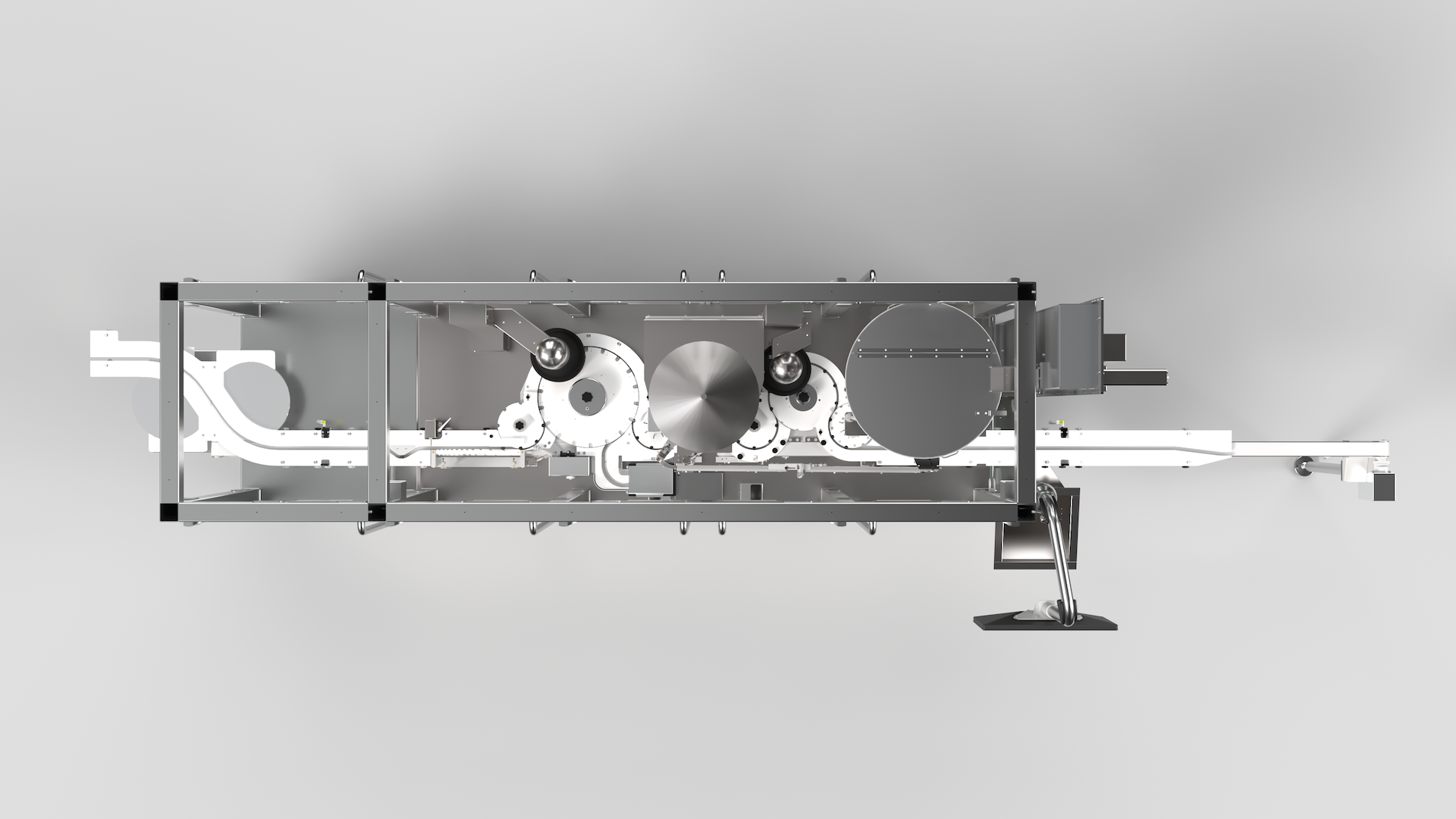

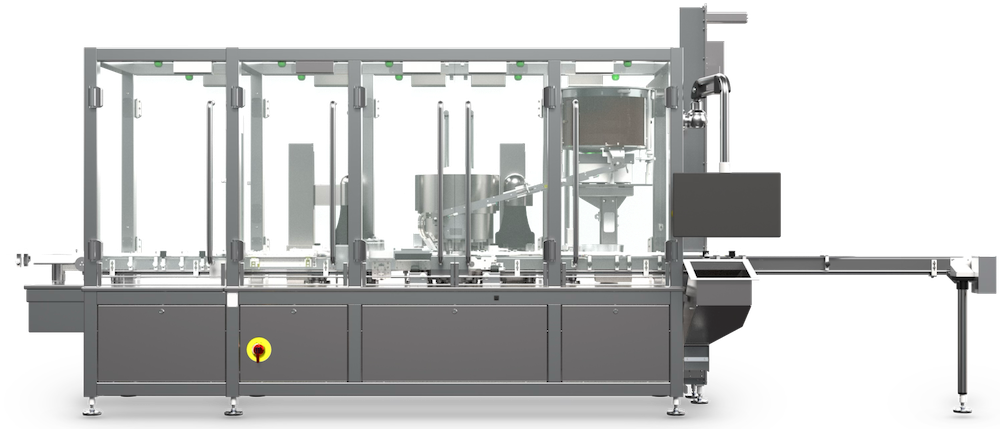

RW Westcapper®: Advanced Design for High-Volume Production

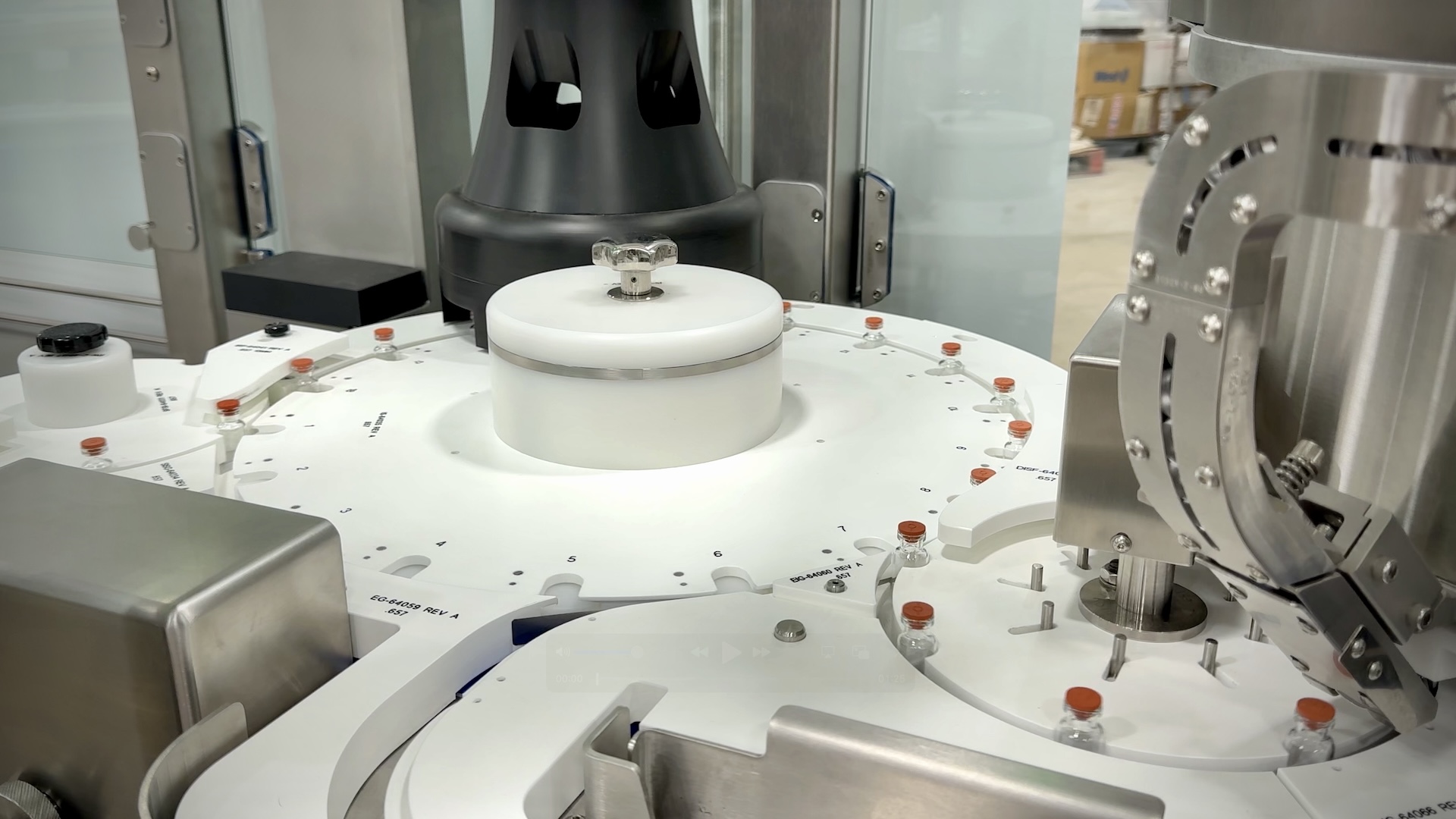

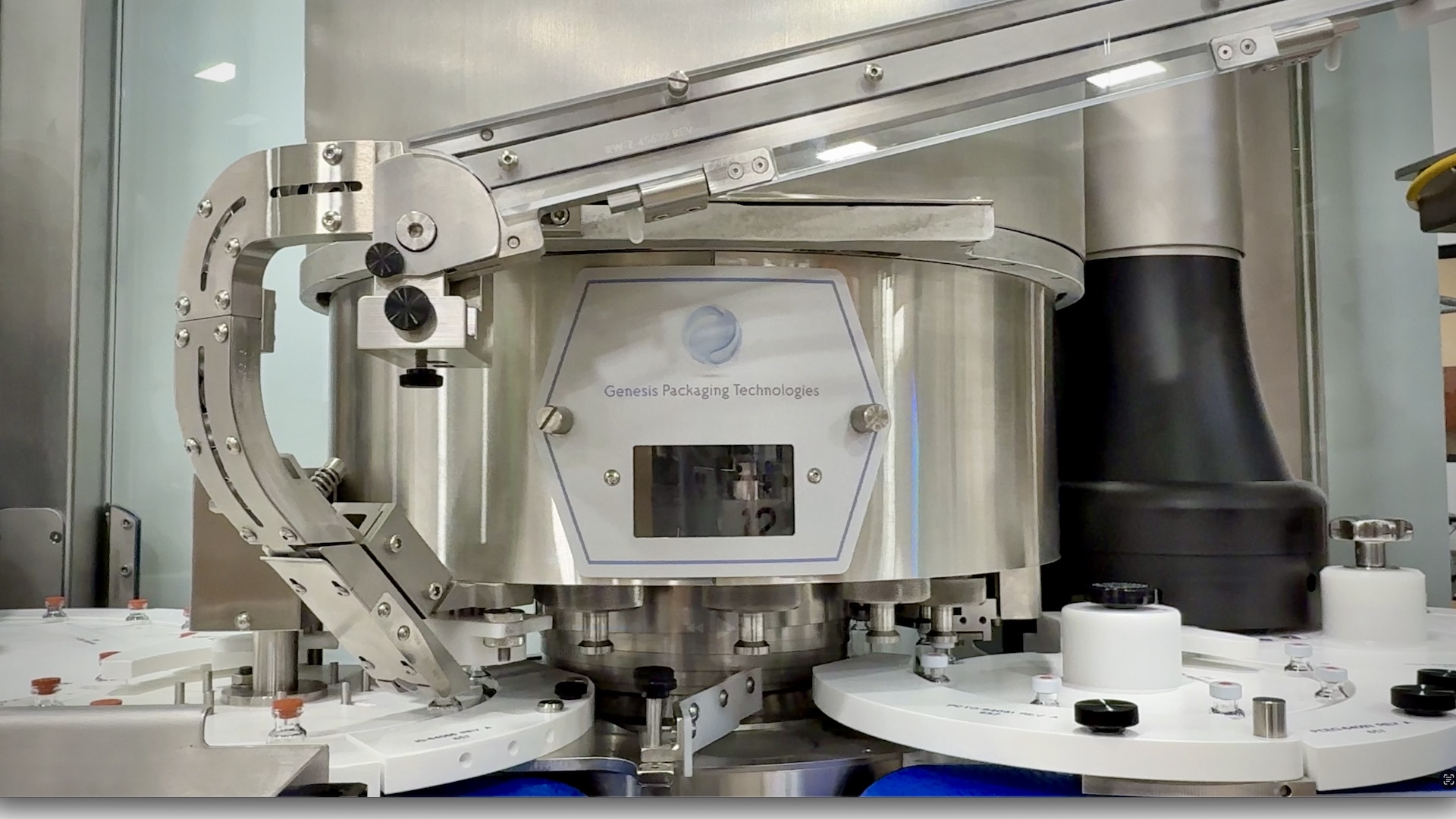

- Optimized Cap Feeding: The vibratory cap bowl is strategically positioned on the discharge side, significantly reducing the risk of particulate contamination during sealing.

- Compact Footprint: Relocating the hopper system away from the head height adjustment mechanism has lowered the machine’s overall height, facilitating integration into various production settings.

- Flexible Configuration: The system accommodates vial flow from left to right as standard, with right-to-left flow available as an option. Conveyor heights range from 35¼″ to 38″, and the standard conveyor length is 98″, with customizable lengths upon request.

- Safety Compliance: An OSHA-compliant safety shield encloses the capping area, with interlocks that halt operation immediately upon shield opening, ensuring operator safety.

Gallery

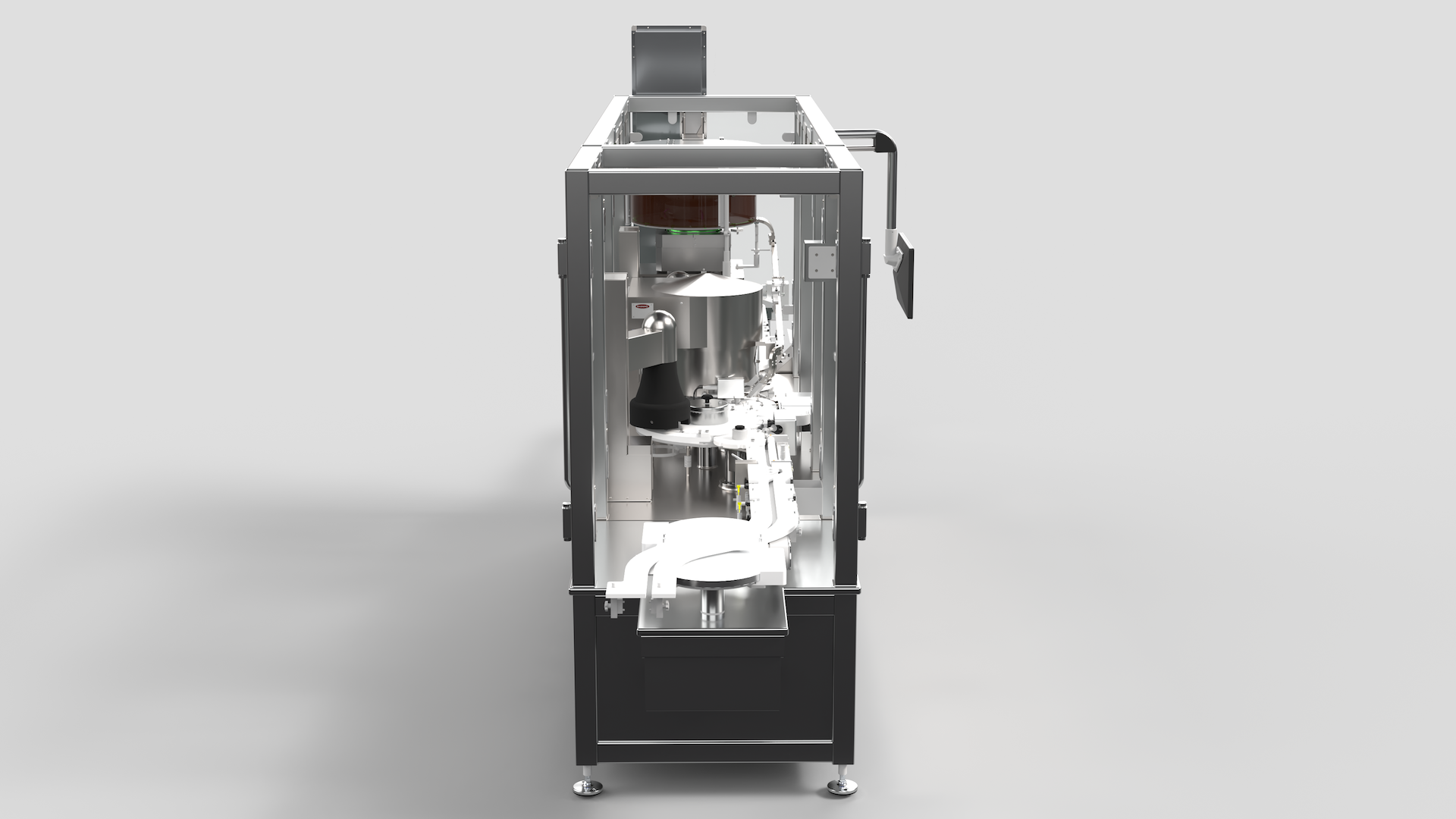

3D Model

Commitment to Seal Integrity and Compliance

- The RW Westcapper® is available with Advisum AI an integrated AI-based vision inspection system that monitors upstream and downstream operations of the sealing process—identifying missing or improperly inserted stoppers before the crimping operation, and detecting improperly sealed vials and cosmetic defects after crimping. This proactive monitoring helps ensure only properly stoppered and sealed vials progress further, reducing potential risks of leakage, contamination, or non-compliance.

- At the core of this capability is Advisum AI, powered by Boon Logic’s AVIS anomaly-detection platform, which leverages unsupervised machine learning to model “normal” compliant units and flag deviations as defects.

-

Key performance attributes include:

- Recipe/training time measured in minutes (e.g., training on ~500 compliant units) rather than the weeks/months typical of traditional supervised vision systems.

- Reduced false rejects (e.g., feasibility studies showing detection accuracies of ~90% with false eject rates of ~6% on challenging products).

- Flexibility to retrofit existing capping machines, integrate into existing visual inspection cabins, or deploy as standalone inspection stations—preserving legacy investments while upgrading inspection capability.

- Typical defect types the system is designed to detect include: missing or raised stoppers, mis-aligned or cocked caps, cracked or chipped vial necks, deformed cap skirts, wrong cap color, particulate contamination under the cap, and cosmetic anomalies.

- Because this inspection is applied both upstream and downstream of the sealing operation, it helps reinforce the entire container closure integrity (CCI) journey—boosting confidence in the sealed vial, reducing rework and scrap, and supporting regulatory expectations for 100% inspection (where required) or robust risk-based inspection strategies.

Comprehensive Services to Support Quality and Compliance

- Stopper Compression Analysis: Genesis provides a detailed service to determine the optimal stopper compression percentage to achieve the desired leak-rate cut-off, correlating this value to Residual Seal Force (RSF) and verifying via standard leak-testing methods. This ensures that the sealing process is tuned for efficacy and repeatability.

- Machine Training Programs: Recognizing that machine performance, change parts, package components, and setup procedures are all inter-related, Genesis offers detailed training and hands-on studies to optimize the interrelationship among these variables — thereby supporting consistent, high-quality oversealing performance.

- Service & Training Packages: Annual service visits, preferred scheduling, and technical support packages are offered to maintain peak machine performance, preserve uptime, and ensure ongoing compliance with evolving standards.

- By combining cutting-edge hardware (like the Westcapper®), advanced inspection (Advisum AI/AVIS), and robust service/training offerings, Genesis Packaging Technologies provides a holistic solution — one that not only equips manufacturers with best-in-class technology but also actively supports them in maintaining high-performance operations and regulatory alignment.

Summary

In short, Genesis’s commitment is two-fold:

- Provide the mechanical sealing excellence via the Westcapper® platform.

- Augment that with AI-driven inspection, training, and service capabilities so that manufacturers can safeguard product integrity, reduce downstream defects, and demonstrate compliance.

Together, these offerings form a comprehensive packaging quality ecosystem — from optimal compression, through sealing, through AI-based inspection and ongoing support.

Annex 1 & Container Closure Integrity (CCI)

EU GMP Annex 1 (revision effective August 25, 2023) emphasizes two critical areas:

- A robust Contamination Control Strategy (CCS), focusing on minimizing particulate and microbial ingress.

- Container Closure Integrity (CCI): ensuring seals prevent leaks and contamination throughout a vial’s shelf life.

Annex 1 Compliance: How Genesis and the RW Westcapper Help You Meet Annex 1 Compliance

Annex 1 Compliance

| Section | Requirement | Westcapper Compliance |

|---|---|---|

| §119 | Particulate control via separate station + air extraction. | FIFO hopper separated from crimp head; air-extraction system installed. |

| §120 | Grade A air protection during capping. | Grade A air supplied over stoppers, seals, and hopper as needed. |

| §121 | Automated rejection of improper stoppers. | Sensors detect and reject missing or raised stoppers pre-crimping. |

| 8.21–8.28* | CCI validation, process monitoring. | Controlled crimp force; RSF analysis; vision-based inspection supports compliance. |

*Last row refers to container-closure provisions embedded in Annex 1 sections 8.21–8.28.

Specifications

18 Spindles

- Max Speed (vpm): 750

- Sealing Technology: Sealing Rail

- Hopper System: Gravity Fed Vibratory

- Seal Size: 13-32mm

- Seal Style: All Standard Serum

- Vial Diameter: 12.7-38.1 mm

- Vial Height: 28.575-158.75 mm

- Construction: Stainless Steel

- Control System: PLC Touchscreen Interface

- Vial Infeed Sensor: Yes

- Jam Control Sensor: Yes

12 Spindles

- Max Speed (vpm): 600

- Sealing Technology: Sealing Rail

- Hopper System: Gravity Fed Vibratory

- Seal Size: 13-32mm

- Seal Style: All Standard Serum

- Vial Diameter: 12.7-57.15 mm

- Vial Height: 28.575-158.75 mm

- Construction: Stainless Steel

- Control System: PLC Touchscreen Interface

- Vial Infeed Sensor: Yes

- Jam Control Sensor: Yes

6 Spindles

- Max Speed (vpm): 300

- Sealing Technology: Sealing Rail

- Hopper System: Gravity Fed Vibratory

- Seal Size: 13-32mm

- Seal Style: All Standard Serum

- Vial Diameter: 12.7-82.55 mm

- Vial Height: 55.549-180.84 mm

- Construction: Stainless Steel

- Control System: PLC Touchscreen Interface

- Vial Infeed Sensor: Yes

- Jam Control Sensor: Yes

Improve Your Crimping Process with Our Partners

SmartSkin Technologies

Instantly Identify Capper Head Issues and Optimize Seal Quality with SmartSkin’s New Single & Multi-Drone Seal Assurance System

Advisum AI Powered by Boon Logic

AI Inspection Solution that has Been Proven to Optimize the Identification of True Rejects While Greatly Reducing the Number of False Rejects.

Change Parts Cabinets

Heavy-Duty Rolling Cabinets for Organizing & Storing All Your Change Parts

Constructed from heavy-duty, powder-coated steel, these cabinets feature industrial casters for effortless mobility, allowing you to position them precisely where needed. Each drawer is custom-designed to organize and store the specific change parts for your capper. Available in two sizes to suit your space and storage requirements.